2-10 Dew Point Air Cooled Refrigerated Air Dryer with R22/ R134A /R407c /R410A Refrigerant for Air Compressor

|

Model |

Flow |

Power |

Connection size |

Length mm |

Width mm |

Height mm |

Weight kg |

|

OSGA-1NF |

1.2 |

0.8 |

1" |

540 |

405 |

495 |

36 |

|

OSGA-2NF |

2.3 |

1 |

1" |

700 |

400 |

787 |

40 |

|

OSGA-3NF |

3.8 |

1 |

1" |

700 |

450 |

850 |

58 |

|

OSGA-5NF |

5.2 |

1.5 |

1 1/2” |

700 |

500 |

870 |

70 |

|

OSGA-6NF |

6.8 |

1.5 |

1 1/2” |

780 |

500 |

890 |

77 |

|

OSGA-10NF |

10.5 |

2 |

2" |

850 |

550 |

960 |

99 |

|

OSGA-12NF |

14 |

3 |

2" |

1160 |

550 |

960 |

121 |

|

OSGA-15NF |

17 |

4 |

DN50 |

1160 |

550 |

1000 |

180 |

|

OSGA-20NF |

24 |

5 |

DN65 |

1200 |

620 |

1250 |

210 |

|

OSGA-25NF |

29 |

6 |

DN80 |

1200 |

850 |

1350 |

350 |

|

OSGA-30NF |

35 |

7 |

DN80 |

1400 |

900 |

1500 |

500 |

|

OSGA-40NF |

42 |

8 |

DN100 |

1400 |

900 |

1500 |

750 |

|

OSGA-50NF |

50 |

10 |

DN100 |

1600 |

1000 |

1600 |

900 |

|

OSGA-60NF |

60 |

12 |

DN125 |

1650 |

1000 |

1650 |

1150 |

|

OSGA-70NF |

70 |

13 |

DN125 |

1650 |

1000 |

1700 |

1300 |

|

OSGA-80NF |

80 |

15 |

DN125 |

1700 |

1100 |

1750 |

1450 |

|

OSGA-100NF |

100 |

20 |

DN150 |

1800 |

1200 |

1800 |

1600 |

|

The company reserves the right to change the design of the product, and the parameters will be changed without prior notice. |

|||||||

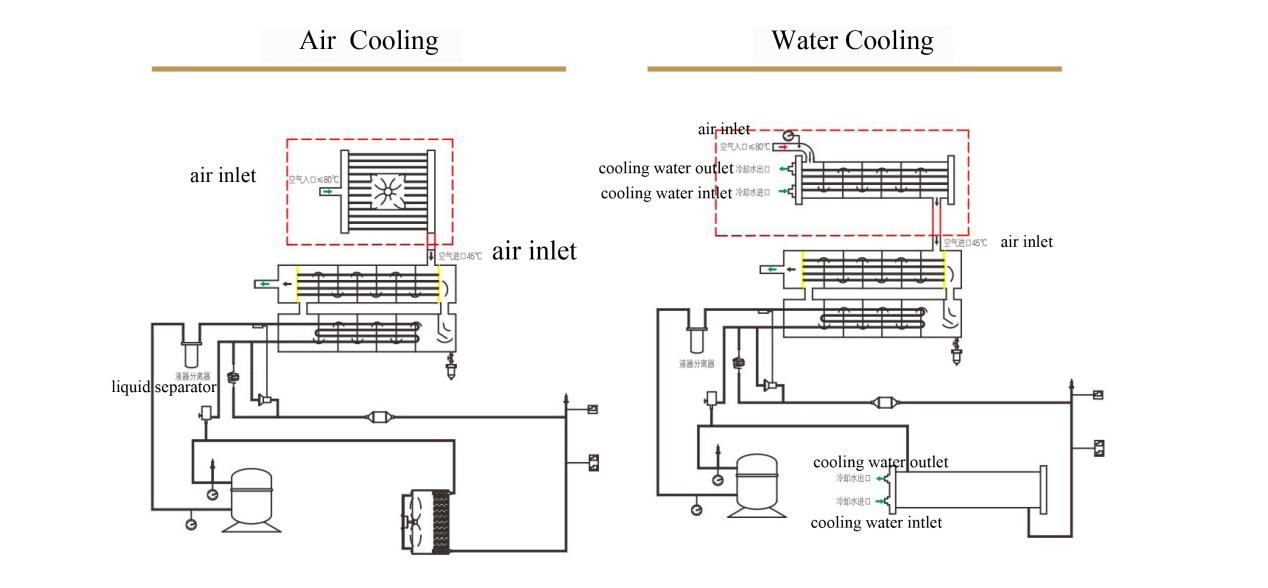

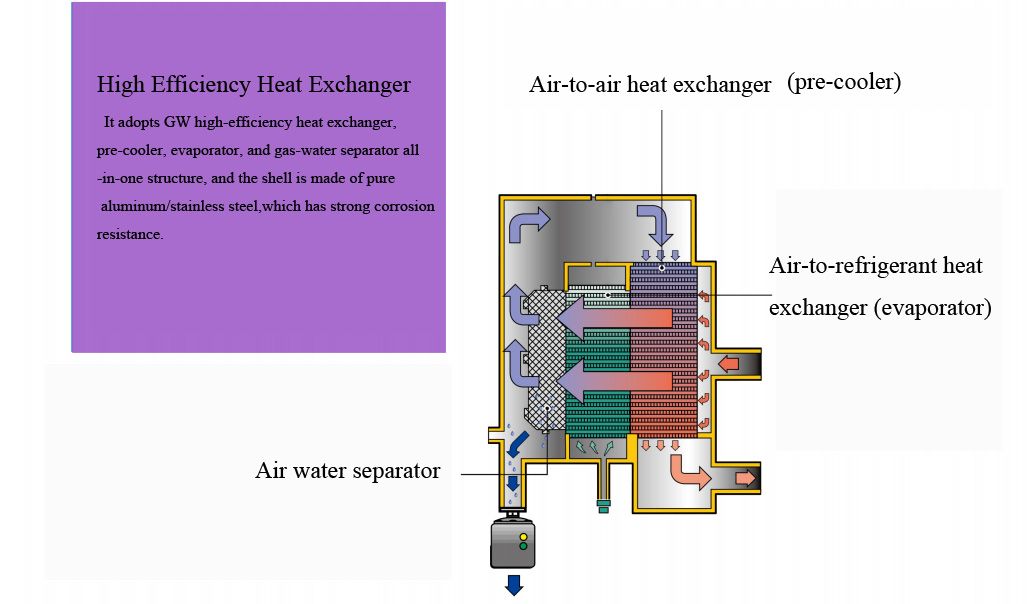

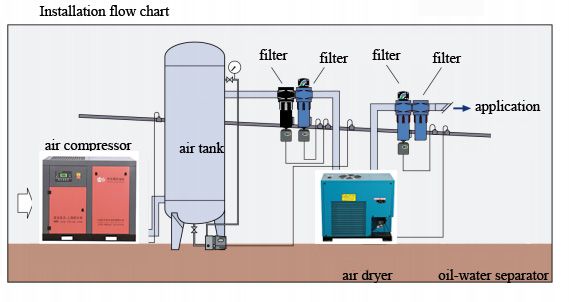

The refrigerated dryer adopts the working principle of cooling and condensation, and is mainly composed of three parts: heat exchange system, refrigeration system and electrical control system. The compressed air first enters the pre-cooler for air-air or air-water heat exchange, and then enters the cold and hot air exchanger to exchange heat with the cooled cold air that has come out of the evaporator to further reduce the temperature of the compressed air. After that, the compressed air enters the evaporator and exchanges heat with the refrigerant. The temperature of the compressed air drops to 0-8°C. The moisture in the air is precipitated at this temperature, separated by the gas-water separator, and then discharged through the automatic drain. The dry low-temperature air enters the hot and cold air exchanger for exchange, and is output after the temperature rises.

For refrigeration and air systems, more than 20% margin is reserved for design parameters.

Refrigeration compressor adopts advanced rotary or scroll type, piston type hermetic refrigeration compressor and semi-hermetic screw refrigeration compressor (above 20HP), operating temperature, low noise, reliable performance, power saving, long life, high energy efficiency ratio, The degree of protection is IP54 (dustproof and splashproof).

The air condenser of the heat exchanger is made of high-quality copper tube with aluminum fins, and the spoiler structure has high heat transfer efficiency, small size and compact structure. The cylinder material is made of stainless steel or carbon steel galvanized to avoid secondary pollution of compressed air.

The equipment structure design is reasonable, easy to maintain, the surface is thermally sprayed, the appearance is beautiful, no rust, no foundation installation, stable operation, low maintenance rate, no consumables, low operating costs, no need for special personnel to wait.