electrical motor PM AC ASD rotary air vaccum pump compressor screw compressor

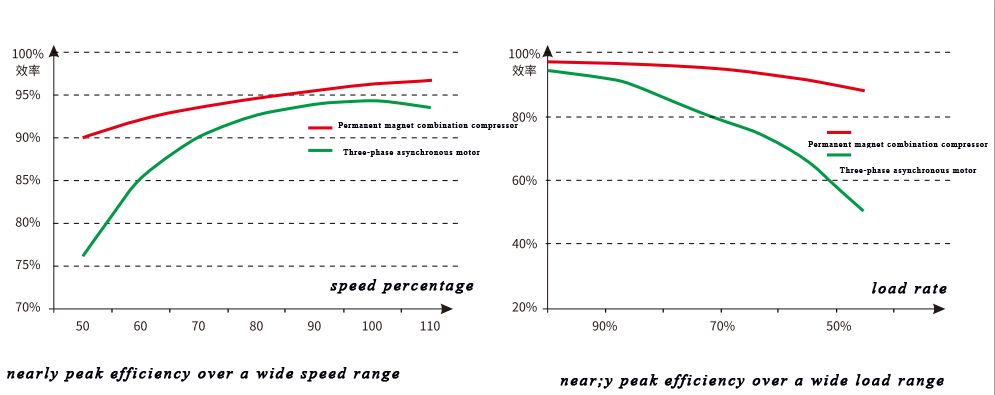

The VPO oil-injected screw vacuum pump adopts an integrated permanent magnet variable frequency special motor, which greatly improves the efficiency of the drive motor, thereby realizing energy saving.

Adopt high coercive force, high temperature resistant permanent magnet, guarantee 150° (no demagnetization;

· Super large torque design, twice the torque of conventional 3000 rpm permanent magnet motor;

· Infinitely variable speed, wide-frequency speed regulation range, field-weakening control is twice that of ordinary permanent magnet motors, easy to change frequency control, good dynamic response performance, fast and wide-range response adjustment, and precise adjustment and control of vacuum degree;

· Frequency conversion adjustment start, smooth start, reduce the impact on the power grid;

Exceeding the first-class energy efficiency, the motor efficiency is as high as 98%, which meets the IES level of IEC 60034-30-1:2014 “Variable Speed AC Motor”;

The high power factor is over 98%, which reduces the pressure on the customer’s power grid, maintains the quality of the power grid, and reduces the apparent current of the equipment.

| Model No. | Power | Flow m³/min m³/h | Pressure | Inlet size | Outlet size | Dimension mm | |

| VPO-5.5PM | 5.5 | 6.4 | 384 | 0.35 | DN80 | DN65 | 1200*890*1000 |

| VPO-7.5PM | 7.5 | 9.2 | 552 | 0.35 | DN80 | DN65 | |

| VPO-11PM | 11 | 11.5 | 690 | 0.35 | DN80 | DN65 | 1850*920*1420 |

| VPO-15PM | 15 | 14.6 | 876 | 0.35 | DN80 | DN65 | |

| VPO-18.5PM | 18.5 | 17.7 | 1062 | 0.35 | DN150 | DN100 | 2000*1000*1600 |

| VPO-22PM | 22 | 22 | 1320 | 0.35 | DN150 | DN100 | |

| VPO-30PM | 30 | 27 | 1620 | 0.35 | DN150 | DN100 | 2300*1120*1765 |

| VPO-37PM | 37 | 30.2 | 1812 | 0.35 | DN150 | DN100 | |

| VPO-45PM | 45 | 44 | 2640 | 0.35 | DN200 | DN150 | 2860*1650*2050 |

| VPO-55PM | 55 | 53 | 3150 | 0.35 | DN200 | DN150 | |

| VPO-75PM | 75 | 75 | 4500 | 0.35 | DN250 | DN200 | 3300*2250*2200 |

| VPO-90PM | 90 | 90 | 5400 | 0.35 | DN250 | DN200 | |

1.Ultimate vacuum 60pa

2.Highly integrated, highly intelligent, the front end of the machine is directly connected to the vacuum pipeline and the power line to start operation, no foundation and other equipment are required, and additional pre-filter equipment may be required under extreme conditions;

3.eneral efficiency 85%

4.Energy saving can reach 25%-40%

glass manufacturing, electronic semiconductors, ceramic bricks, paper trays, printing and dyeing, food packaging, wood processing, tobacco production, bottle making, composite materials, vacuum simulation, aerospace.