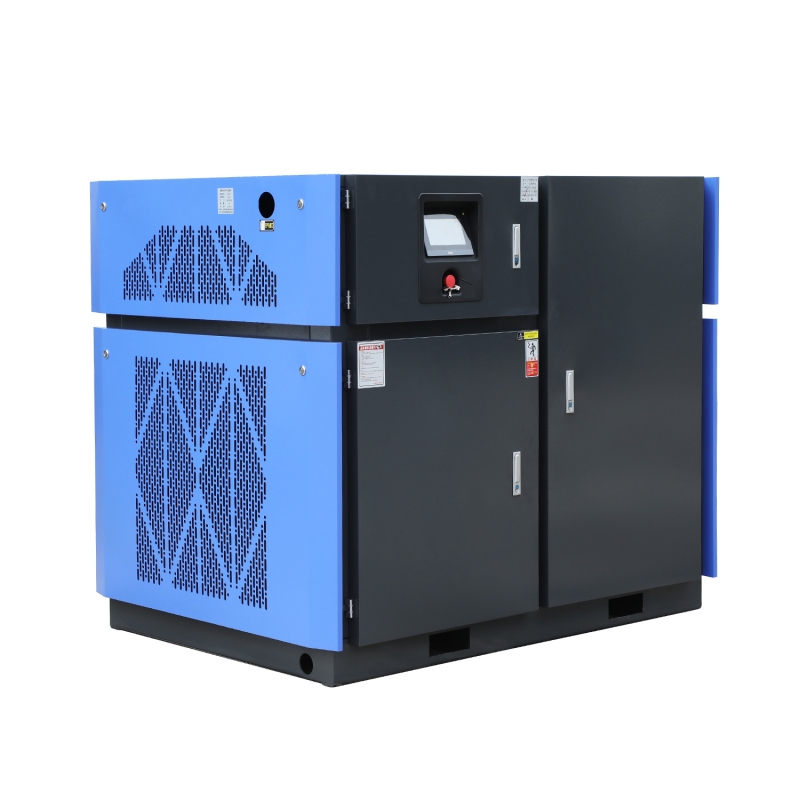

Horizontal two-stage pressure screw air compressor Two Stage Screw Air Compressor Electric Screw Air Compressor Price

| Model | ETSVII-22A | ETSVII-37A | ETSVII-45A | ETSVII-55A | ETSVII-75A | ETSVII-90A | ETSVII-110A | ETSVII-132A | |

| air flow/ pressure (M3/min/ Mpa) | 4.1/0.7 | 6.9/0.7 | 8.9/0.7 | 11.2/0.7 | 15.1/0.7 | 20.0/0.7 | 22.0/0.7 | 26.0/0.7 | |

| 4.0/0.8 | 6.8/0.8 | 8.8/0.8 | 11.0/0.8 | 15.0/0.8 | 19.8/0.8 | 21.2/0.8 | 25.8/0.8 | ||

| 3.4/1.0 | 6.2/1.0 | 7.8/1.0 | 9.7/1.0 | 12.4/1.0 | 17.9/1.0 | 19.8/1.0 | 23.5/1.0 | ||

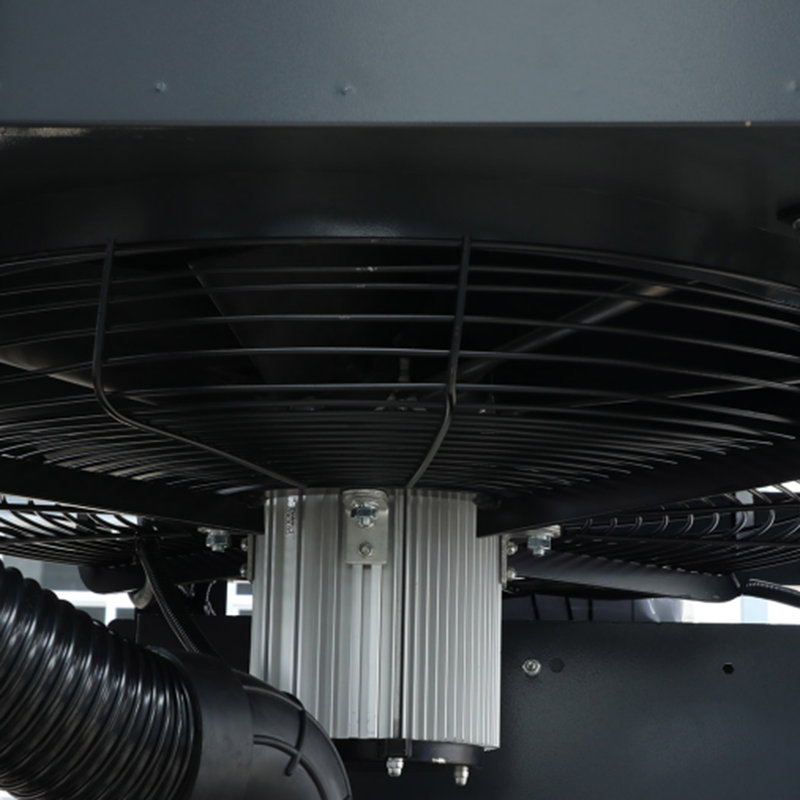

| Air supply temperature |

≤ambient temperature +8~15ºC |

||||||||

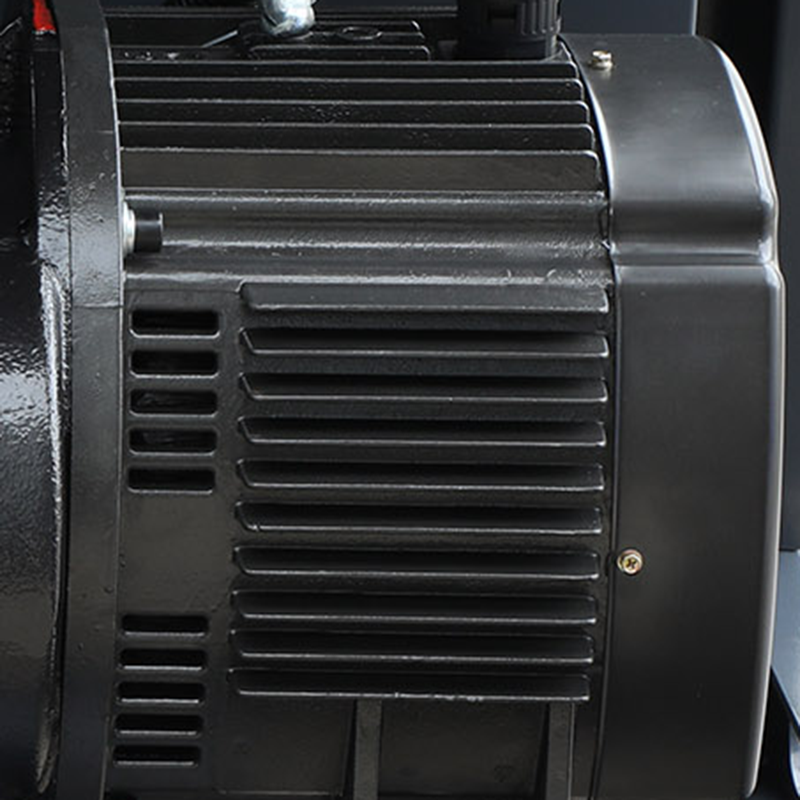

| Motor | Power (kw/hp) | 22/30 | 37/50 | 45/60 | 55/75 | 75/100 | 90/120 | 110/150 | 132/175 |

| Start method |

VSD start |

||||||||

| Voltage (v/hz) |

380V 3PH 50HZ /other voltagesd can be customized ) |

||||||||

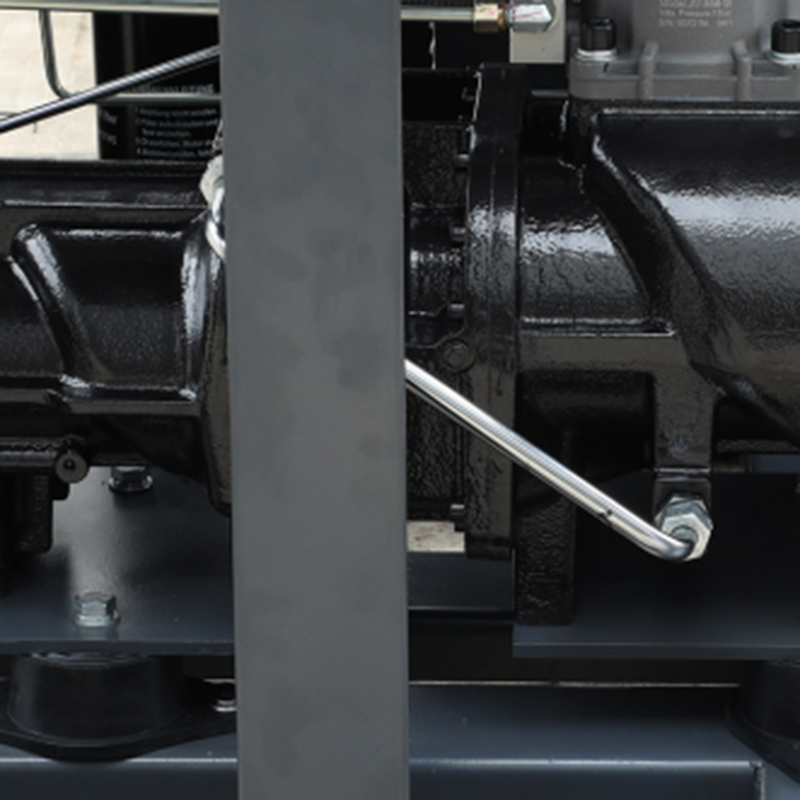

| Drive method |

intergrade air end and motor |

||||||||

| Oil content (PPM) |

≤3 |

||||||||

| Connector inch | 1" | 1 1/2" | 2" | 2" | 2" | 2 1/2" | 2 1/2" | 2 1/2" | |

| Dimension | length mm | 1254 | 1455 | 1754 | 7854 | 1914 | 2454 | 2454 | 2454 |

| width mm | 900 | 1100 | 1200 | 1300 | 1300 | 1500 | 1500 | 1500 | |

| height mm | 1190 | 1300 | 1550 | 1550 | 1600 | 1840 | 1840 | 1840 | |

| Weight (kg) | 450 | 580 | 925 | 970 | 1170 | 1746 | 1750 | 1790 | |

1. Electric power industry, instrumentation, ash removal, factory miscellaneous compressed air systems, water treatment including boiler feed water treatment and industrial wastewater treatment systems, and hydropower stations will also have compressed air systems for equipment power.

2. Chemical fiber industry, cotton spinning industry; chemical fiber industry mainly uses gas for instrumentation and suction guns, printing and dyeing mainly uses gas for power and instrumentation.

3. Metallurgical industry, divided into iron and steel industry and non-ferrous metal smelting and manufacturing industry.

4. In the aerospace industry, because pneumatic devices can withstand radiation and high temperature, they can also withstand large acceleration speeds, so they are widely used in the control of modern aircraft, rockets, and missiles.

4. In the iron and steel industry, it is used as gas supply for power equipment and pneumatic tools, surface gas, surface cleaning, and non-ferrous metal smelting.

5. It is used in gas-assisted injection molding technology in the injection molding industry.

6. In the glass industry, it is used for back blowing of cloth bags or filter cartridges for dust collection equipment such as glass equipment dust collectors and self-cleaning air filters.

7. Electronics, experiments, and precision instrument industries.

8.Other industries: automobile manufacturing, ore mining, large amusement parks, etc.

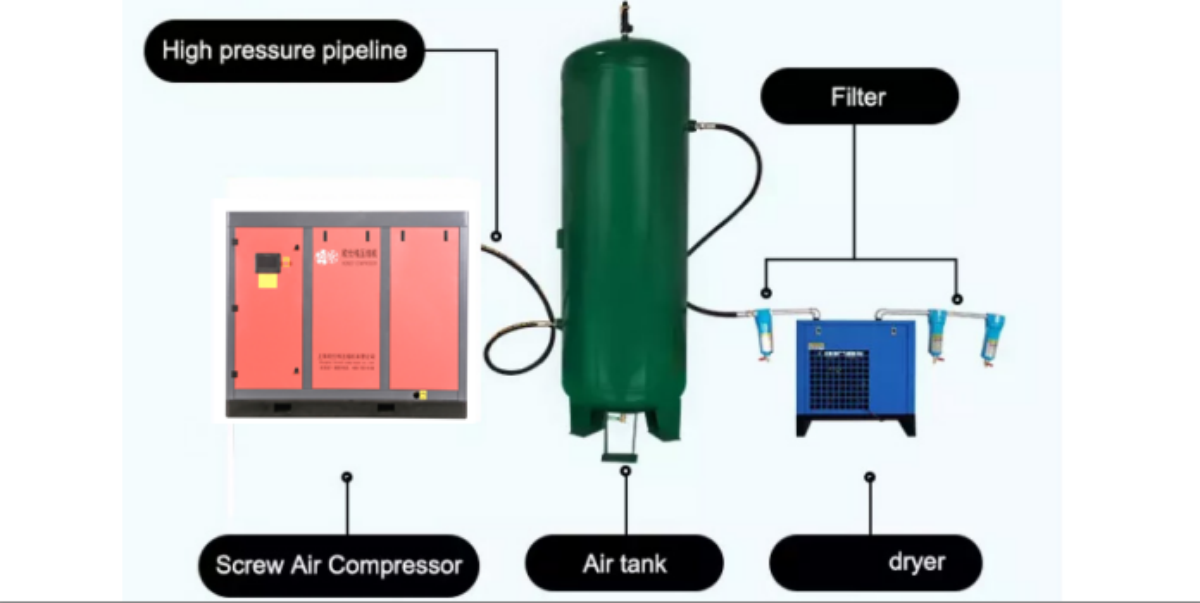

Air compressor < ValveAir < tank < FilterAir < dryer < Filter < Filter < Filter