News

-

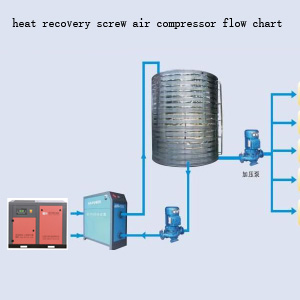

OSG screw air compressorwaste heat recovery concept and working principle

OSG screw air compressorwaste heat recovery concept and working principle Compressed Air Technology Exhibition understands that while the OSG screw air compressorindustry is frantically chasing equipment energy efficiency, improving energy reuse through OSG screw air compressorwaste heat recovery...Read more -

Why is it said: Air compressor waste heat recovery is a “good business”?

According to analysis, when the OSG screw air compressor waste heat is recycled, the waste heat recovery equipment absorbs most of the heat energy of the OSG screw air compressor system, so that the operating temperature of the OSG screw air compressor can be maintained between 65-85 degrees, all...Read more -

The differences between the two structures of screw air compressor and piston air compressor

Piston air compressor: The crankshaft drives the piston to reciprocate, changing the cylinder volume for compression. Screw air compressor: The male and female rotors operate continuously, changing the cavity volume for compression. 2. Specific differences in operation: Pistonair compresso...Read more -

There are so many ways to control the displacement of screw air compressors! Did you know everything?

01 Gas volume control and adjustment 80% of the total cost of compressed air is reflected in energy consumption. Therefore, for different types of screw air OSG screw air compressors, different control and regulation systems should be selected according to different regulation systems. Differenc...Read more -

The whole process of three filter maintenance of OSG oil injection screw air compressor

Screw air compressor refers to the compressor whose compression medium is air. It is widely used in mechanical mining, chemical industry, petroleum, transportation, construction, navigation and other industries. Its users almost include all sectors of the national economy, with a large vol...Read more -

Why use compressed air for laser cutting? How to choose a special screw air compressor?

Laser cutting is the use of high-power density laser beams to irradiate the material to be cut, so that the material is quickly heated to the vaporization temperature, and holes are formed after evaporation. As the beam moves to the material, the holes continuously form a narrow width (such as ab...Read more -

How much do you know about compressed air?

1. What is air? What is normal air? Answer: The atmosphere around the earth, we are used to call it air. The air under the specified pressure of 0.1MPa, temperature of 20°C, and relative humidity of 36% is normal air. Normal air differs from standard air in temperature and contains moisture. When...Read more -

Causes and treatment methods of motor bearing overheating

Bearings are the most important supporting parts of motors. Under normal circumstances, when the temperature of the motor bearings exceeds 95°C and the temperature of the sliding bearings exceeds 80°C, the bearings are overheated. Bearing overheating when the motor is running is a common fault, a...Read more -

What is air source equipment? What equipment is there?

What is air source equipment? What equipment is there? The air source equipment is the generating device of compressed air – air compressor (air compressor). There are many types of air compressors, common ones are piston type, centrifugal type, screw type, sliding vane type, scroll ...Read more -

Air Blower classification and subdivision product comparison from SHANGHAI HONEST COMPRESSOR CO.,LTD

Blower classification and subdivision product comparison The blower refers to the fan whose total outlet pressure is 30-200kPa under the design conditions. According to different structures and working principles, blowers...Read more -

Knowledge of compressed air system

Compressed air system, in a narrow sense, is composed of air source equipment, air source purification equipment and related pipelines. In a broad sense, pneumatic auxiliary components, pneumatic actuators, pneumatic control components, vacuum components, etc. all belong to the category of compre...Read more -

Air compressor service failure?

Complaints from compressor customers are mainly due to service failures by companies or salespersons. When a service failure occurs, different customers may react differently. As for the way and intensity of the customer’s reaction, it is closely related to the following three factors: the ...Read more

-

E-mail

-

WeChat

WeChat

-

Whatsapp

Whatsapp

-

Phone

-

Top