Screw air compressor refers to the compressor whose compression medium is air. It is widely used in mechanical mining, chemical industry, petroleum, transportation, construction, navigation and other industries. Its users almost include all sectors of the national economy, with a large volume and a wide range. . As far as professional compressor manufacturers and professional agents are concerned, its follow-up maintenance and maintenance work is very difficult, especially in the hot summer, due to heavy maintenance tasks and heavy workload, it often happens that emergency repairs are not timely; In other words, in order to ensure safe production, it is necessary to master the routine maintenance of air compressors. Today, I will briefly introduce some common sense in the maintenance of oil-injected screw air compressors.

Screw air compressor refers to the compressor whose compression medium is air. It is widely used in mechanical mining, chemical industry, petroleum, transportation, construction, navigation and other industries. Its users almost include all sectors of the national economy, with a large volume and a wide range. . As far as professional compressor manufacturers and professional agents are concerned, its follow-up maintenance and maintenance work is very difficult, especially in the hot summer, due to heavy maintenance tasks and heavy workload, it often happens that emergency repairs are not timely; In other words, in order to ensure safe production, it is necessary to master the routine maintenance of air compressors. Today, I will briefly introduce some common sense in the maintenance of oil-injected screw air compressors.

1. Before maintenance

(1) Prepare the required spare parts according to the model of the screw air compressor being maintained. Communicate and coordinate with the production department on site, confirm the units that need maintenance, hang safety signs, and isolate warning areas.

(2) Confirm that the unit is powered off. Close the high pressure outlet valve.

(3) Check the leakage status of each pipeline and interface in the unit, and deal with any abnormality.

(4) Drain the old cooling oil: Connect the pipe network pressure port with the system pressure port in series, open the outlet valve, use the air pressure to discharge the old cooling oil, and at the same time, drain the waste oil as much as possible from the handpiece head. Finally close the outlet valve again.

(5) Check the condition of the machine head and main motor. The handpiece head should rotate smoothly for several turns. If there is any blockage, the belt or coupling can be removed if necessary to determine whether it is a head failure or a main motor failure.

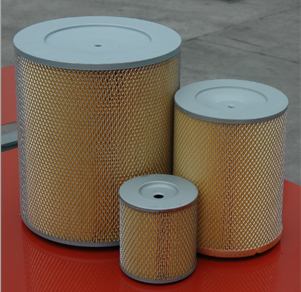

Air filter replacement process

Open the back cover of the air filter, unscrew the nut and washer assembly that fixes the filter element, take out the filter element, and replace it with a new one. Remove the air filter element for visual inspection, and clean the air filter element by blowing with compressed air. If the filter element is seriously dirty, blocked, deformed or damaged, the air filter element must be replaced; the dust storage bin of the air filter cover must be cleaned.

If the inferior air filter is used, the oil separator core will be dirty and blocked, and the lubricating oil will deteriorate rapidly. If the air filter element is blown dust irregularly, it will be clogged, which will reduce the intake air volume and reduce the air compression efficiency. If the filter element is not replaced regularly, it may cause the negative pressure to increase and be sucked through, the dirt will enter the machine, block the filter and the oil separation core, cause the cooling oil to deteriorate, and the main engine will wear out.

3. Oil filter replacement process

(1) Use a band wrench to remove the old element and gasket.

(2) Clean the sealing surface and apply a layer of clean compressor oil on the new gasket. The new oil filter must be filled with oil and then tightened in place to avoid damage to the main engine bearing due to short-term oil shortage. Hand tighten the new element, again using a band wrench 1/2-3/4 turn.

The risk of replacing inferior oil filters is: insufficient flow, resulting in high temperature of the air compressor and burning of the head due to lack of oil. If the oil filter is not replaced regularly, the front and rear pressure difference will increase, the oil flow will decrease, and the exhaust temperature of the main engine will increase.

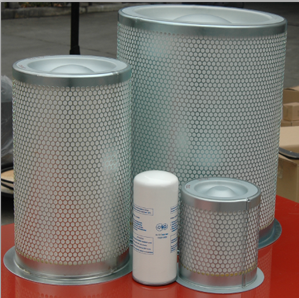

Fourth, replace the oil separator filter eleme

(1) Release the pressure in the oil-gas separator tank and pipeline, disassemble all the pipelines and bolts connected to the oil-gas separator gland, and remove the oil-gas separator filter element that is sleeved together by the gland.

(2) Check whether there is rust and dust in the container. After cleaning, put the new separator filter element into the cylinder body, install the gland and restore it, insert the oil return pipe 3-5mm away from the bottom of the filter element, and clean all the pipelines.

(3) The staple on the new oil separator is specially designed to prevent static electricity, and it must not be removed, as it will not affect the seal.

(4) Before installing the new oil component, oil must be applied to the gasket to facilitate next disassembly.

If inferior oil separators are used for maintenance, problems such as poor separation effect, large pressure drop, and large oil content at the outlet will result.

The oil separation core is not replaced regularly: it will lead to excessive pressure difference between the front and rear and breakdown, and the cooling lubricating oil will enter the pipeline along with the air.

5. Replace lubricating oil

(1) Fill the unit with new oil to the standard position. You can refuel at the filler port or from the oil separator base before installing the oil separator.

(2) Too much oil is added to the screw engine, and the liquid level exceeds the upper limit, which will cause the initial separation effect of the oil separation barrel to deteriorate, and the oil content of the compressed air passing through the oil separation core will increase, exceeding the oil treatment capacity and the oil return of the oil return pipe. Increase the oil content after refining. Stop the machine to check the oil level, and ensure that the oil level is between the upper and lower scale lines when the machine is stopped.

(3) The oil quality of the screw engine is not good, and the performance is poor in defoaming, anti-oxidation, high temperature resistance, and anti-emulsification.

(4) If different grades of oil are mixed, the oil will deteriorate or gel, causing the oil separator core to be blocked and deformed, and the compressed air containing oil will be discharged directly.

(5) The quality of the oil is reduced, the lubricating performance is reduced, and the wear of the machine is aggravated. The oil temperature rises, which affects the working efficiency and life of the machine. Serious oil pollution may cause damage to the machine.

6. Check the belt

(1) Check the pulley drive position, V-belt and belt tensioner.

(2) Use a ruler to check whether the pulleys are on the same plane, and adjust if necessary; visually inspect the belt, if the V-belt sinks deep into the V-groove of the pulley, it is severely worn or the belt has aging cracks, and the entire V-belt must be replaced; check the belt Tensioner, adjust the spring to the standard position if necessary.

7. Clean the cooler

(1) The air cooler needs to be purged regularly, and when it is shut down, use compressed air to purge from top to bottom above the cooler.

(2) Be careful not to damage the cooling fins when purging, and avoid cleaning with hard objects such as iron brushes.

Eight, the maintenance is completed and the commissioning is completed

After the maintenance of the whole machine is completed, test the machine. The test machine requires that the vibration, temperature, pressure, motor operating current, and control all reach the normal range value, and there is no oil leakage, water leakage, air leakage and other phenomena. If any abnormal situation is found during the debugging process, it should be stopped immediately for inspection, and then restarted for use after eliminating the problem.

Post time: Aug-28-2023