Why do permanent magnet synchronous motors become the main drive motors?

The electric motor can convert electrical energy into mechanical energy, and transfer the mechanical energy to the wheels through the transmission system to drive the vehicle. It is one of the core drive systems of new energy vehicles. At present, the commonly used drive motors in new energy vehicles are mainly permanent magnet synchronous motors and AC asynchronous motors. Most new energy vehicles use permanent magnet synchronous motors. Representative car companies include BYD, Li Auto, etc. Some vehicles use AC asynchronous motors. Electric motors represent car companies such as Tesla and Mercedes-Benz.

An asynchronous motor is mainly composed of a stationary stator and a rotating rotor. When the stator winding is connected to the AC power supply, the rotor will rotate and output power. The main principle is that when the stator winding is energized (alternating current), it will form a rotating electromagnetic field, and the rotor winding is a closed conductor that continuously cuts the stator's magnetic induction lines in the stator's rotating magnetic field. According to Faraday's law, when a closed conductor cuts the magnetic induction line, a current will be generated, and the current will generate an electromagnetic field. At this time, there are two electromagnetic fields: one is the stator electromagnetic field connected to the external alternating current, and the other is generated by cutting the stator electromagnetic induction line. Rotor electromagnetic field. According to Lenz's law, the induced current will always resist the cause of the induced current, that is, try to prevent the conductors on the rotor from cutting the magnetic induction lines of the stator's rotating magnetic field. The result is: the conductors on the rotor will "catch up" with the stator's The rotating electromagnetic field means that the rotor chases the rotating magnetic field of the stator, and finally the motor starts to rotate. During the process, the rotation speed of the rotor (n2) and the rotation speed of the stator (n1) are out of sync (the speed difference is about 2-6%). Therefore, it is called an asynchronous AC motor. On the contrary, if the rotation speed is the same, it is called a synchronous motor.

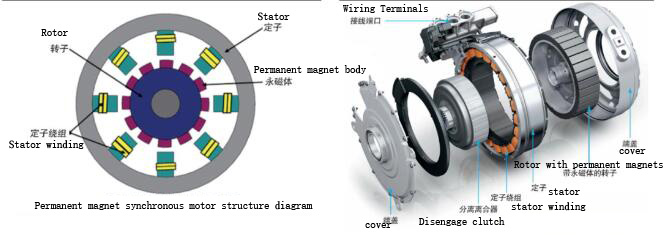

The permanent magnet synchronous motor is also a type of AC motor. Its rotor is made of steel with permanent magnets. When the motor is working, the stator is energized to generate a rotating magnetic field to push the rotor to rotate. "Synchronization" means that the rotation of the rotor during steady-state operation The speed is synchronized with the rotational speed of the magnetic field. Permanent magnet synchronous motors have a higher power-to-weight ratio, are smaller in size, lighter in weight, have larger output torque, and have excellent limit speed and braking performance. Therefore, permanent magnet synchronous motors have become the most widely used electric vehicle today. of electric motor. However, when the permanent magnet material is subjected to vibration, high temperature and overload current, its magnetic permeability may decrease, or demagnetization may occur, which may reduce the performance of the permanent magnet motor. In addition, rare earth permanent magnet synchronous motors use rare earth materials, and the manufacturing cost is not stable.

Compared with permanent magnet synchronous motors, asynchronous motors need to absorb electric energy for excitation when working, which will consume electric energy and reduce the efficiency of the motor. Permanent magnet motors are more expensive due to the addition of permanent magnets.

Models that choose AC asynchronous motors tend to give priority to performance and take advantage of the performance output and efficiency advantages of AC asynchronous motors at high speeds. The representative model is the early Model S. Main features: When the car is driving at high speed, it can maintain high-speed operation and efficient use of electric energy, reducing energy consumption while maintaining maximum power output;

Models that choose permanent magnet synchronous motors tend to prioritize energy consumption and utilize the performance output and efficient operation of permanent magnet synchronous motors at low speeds, making them suitable for small and medium-sized cars. Its characteristics are small size, light weight, and extended battery life. At the same time, it has good speed regulation performance and can maintain high efficiency when faced with repeated starts, stops, accelerations and decelerations.

Permanent magnet synchronous motors dominate. According to statistics from the "New Energy Vehicle Industry Chain Monthly Database" released by the Advanced Industry Research Institute (GGII), the domestic installed capacity of new energy vehicle drive motors from January to August 2022 was approximately 3.478 million units, a year-on-year increase of 101%. Among them, the installed capacity of permanent magnet synchronous motors was 3.329 million units, a year-on-year increase of 106%; the installed capacity of AC asynchronous motors was 1.295 million units, a year-on-year increase of 22%.

Permanent magnet synchronous motors have become the main drive motors in the pure electric passenger car market.

Judging from the selection of motors for mainstream models at home and abroad, new energy vehicles launched by domestic SAIC Motor, Geely Automobile, Guangzhou Automobile, BAIC Motor, Denza Motors, etc. all use permanent magnet synchronous motors. Permanent magnet synchronous motors are mainly used in China. First, because permanent magnet synchronous motors have good low-speed performance and high conversion efficiency, which are very suitable for complex working conditions with frequent starts and stops in urban traffic. Second, because of the neodymium iron boron permanent magnets in permanent magnet synchronous motors. The materials require the use of rare earth resources, and my country has 70% of the world's rare earth resources, and the total output of NdFeB magnetic materials reaches 80% of the world, so China is more keen on using permanent magnet synchronous motors.

Foreign Tesla and BMW use permanent magnet synchronous motors and AC asynchronous motors to develop collaboratively. From the perspective of application structure, permanent magnet synchronous motor is the mainstream choice for new energy vehicles.

The cost of permanent magnet materials accounts for about 30% of the cost of permanent magnet synchronous motors. The raw materials for manufacturing permanent magnet synchronous motors mainly include neodymium iron boron, silicon steel sheets, copper and aluminum. Among them, the permanent magnet material neodymium iron boron is mainly used to make rotor permanent magnets, and the cost composition is about 30%; silicon steel sheets are mainly used to make customized The cost composition of the rotor core is about 20%; the cost composition of the stator winding is about 15%; the cost composition of the motor shaft is about 5%; and the cost composition of the motor shell is about 15%.

Why are OSG permanent magnet motors screw air compressor more efficient?

The permanent magnet synchronous motor is mainly composed of stator, rotor and shell components. Like ordinary AC motors, the stator core has a laminated structure to reduce iron loss due to eddy current and hysteresis effects when the motor is running; the windings are also usually three-phase symmetrical structures, but the parameter selection is quite different. The rotor part has various forms, including a permanent magnet rotor with a starting squirrel cage, and an embedded or surface-mounted pure permanent magnet rotor. The rotor core can be made into a solid structure or laminated. The rotor is equipped with permanent magnet material, which is commonly called magnet.

Under normal operation of the permanent magnet motor, the rotor and stator magnetic fields are in a synchronous state. There is no induced current in the rotor part, and there is no rotor copper loss, hysteresis, or eddy current loss. There is no need to consider the problem of rotor loss and heating. Generally, the permanent magnet motor is powered by a special frequency converter and naturally has a soft start function. In addition, the permanent magnet motor is a synchronous motor, which has the characteristic of adjusting the power factor through the intensity of the excitation, so the power factor can be designed to a specified value.

From the starting point of view, due to the fact that the permanent magnet motor is started by a variable frequency power supply or a supporting inverter, the starting process of the permanent magnet motor is very easy; it is similar to the starting of a variable frequency motor, and avoids the starting defects of ordinary cage asynchronous motors.

In short, the efficiency and power factor of permanent magnet motors can reach very high, the structure is very simple, and the market has been very hot in the past ten years.

However, loss of excitation failure is an unavoidable problem in permanent magnet motors. When the current is too large or the temperature is too high, the temperature of the motor windings will rise instantaneously, the current will increase sharply, and the permanent magnets will rapidly lose excitation. In the permanent magnet motor control, an over-current protection device is set to avoid the problem of the motor stator winding being burned, but the resulting loss of excitation and equipment shutdown are inevitable.

Post time: Dec-12-2023