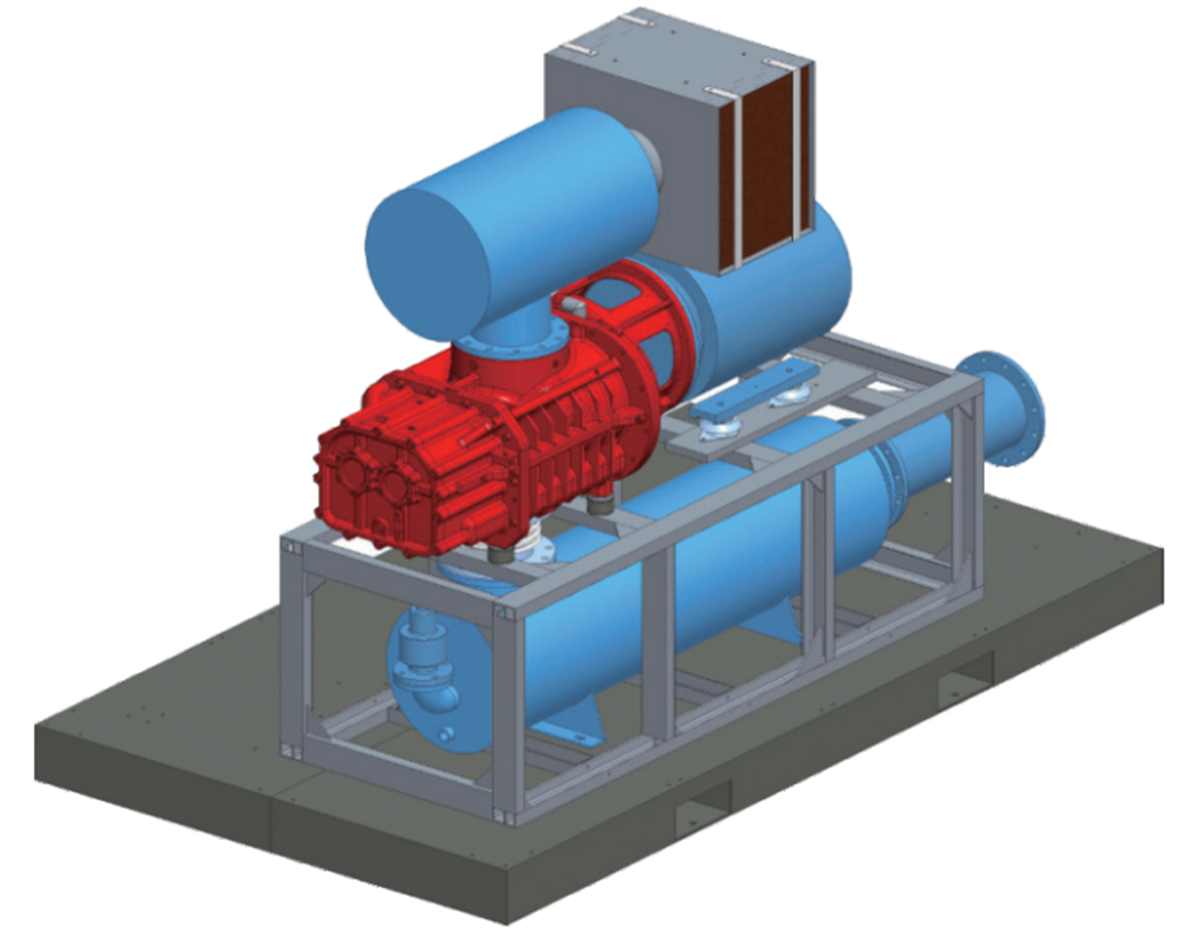

Industrial Oil Free Vsd Screw Air Blower /Vacuum Pump With Inverter and Pm Motor

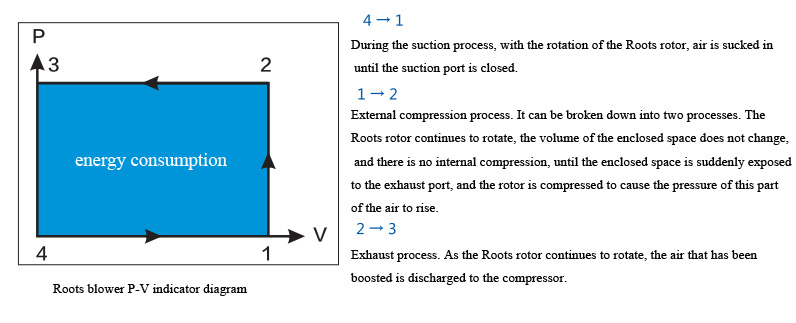

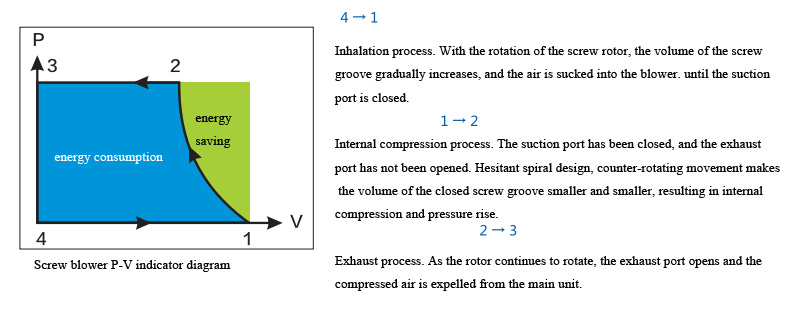

Under the same air volume and air pressure, the power consumption required by the screw blower is much smaller. The green part in the figure is the saved energy consumption. Compared with the traditional Roots blower, the screw blower may save up to 35%, the higher the pressure, the more significant the energy saving effect, and the average energy saving is 20%. The energy saving of oil-free blower can reach 20%-50%.

The Roots blower has no internal compression, so when the exhaust is exhausted, the higher-pressure air in the pipe network is reversely charged back into the compression chamber, forming gas ramming, which produces high low-frequency air noise, and the vibration of the equipment is also very large, which greatly reduces the pressure of the screw fan. Reduced noise and vibration, 15-30dB lower than Roots blower noise (A)

1. Sewage treatment

Whether it is municipal sewage or corporate sewage (including textile printing and dyeing, leather, medicine, chemical industry, paper making, breeding and slaughtering, etc.), it must be treated up to the standard before it can be discharged into natural water bodies or recycled. In the sewage treatment process, a key link is the oxygen supply for biological treatment, that is, the aeration link. During the operation of several common process sewage treatment plants, the energy consumption of the oxygen supply system for biological treatment accounts for 50%-55% of the energy consumption of the whole plant. There is a lot of room for reducing the consumption of the biological treatment oxygen supply system. Choosing an efficient blower will directly bring considerable economic benefits.

2. Pneumatic conveying-dilute phase-powder conveying in cement plant-powder conveying in petrochemical industry

Lower energy costs (up to 80% of blower life cycle costs), innovative screw blower technology resulting in less downtime for maintenance.

3. Fermentation

Lower energy costs (up to 80% of blower life cycle costs), innovative screw blower technology for lower maintenance downtime, extremely wide flow and pressure operating ranges Nonwoven production, air knife, texturing flow Adjustable to influence fiber properties, energy efficient blower capable of continuous 24/7 operation with low operating costs. Point-of-use installation without noise protection measures.

4. Desulfurization and denitrification

In thermal power generation, steel, glass, chemical and other factories, a large number of boilers are burned, and the flue gas emitted by them contains a large amount of sulfur, nitrate and other substances, which seriously pollutes the atmosphere. This requires treatment such as desulfurization and denitrification before discharge, and can only be discharged into the atmosphere after reaching the standard. In desulfurization and denitrification facilities, oil-free screw blowers are required as oxidation fans.