Products

-

7.5kw 15kw 22kw 37kw 55kw Silent Electric Type Constant Frequency Screw Air Compressor

7.5kw 15kw 22kw 37kw 55kw Silent Electric Type Constant Frequency Screw Air Compressor

I. Introduction:Main features of oil-lubricated screw air compressor:1.Imported top-grade air end, as the third generation product of state-of -the-art brand in the world, with asymmetrical 5:6 tooth rotors, is provided with outstanding performance and high efficiency far beyond other similar-type brands.

2. Full-intellectual control system and LCD screen, with self-diagnosis and protection devices; remote control and multi-host interlock control, realizing unattended and high -tech operation.

3.Y series three-phase asynchronous motor special for compressor, imported SKF bearing, F-level insulation, IP54, especially suitable for long-term use, safe and reliable.

4. Imported oil filter, oil-air separation filter cartridge to ensure oil content<3PPM; the trunk adopts metal pipe, safe for long-term operation without leakage or deformation; the V-type drive belt is imported from Germany, and has a service life>10000hours.

5. Air volume auto-intelligent control, auto shutdown after long idle run to ensure over 25% of energy saving.

6. Valve oil-free system design, achieving a safer and more reliable operation of the whole machine; main machine adopts one imported special compressor oil, reducing the leakage inside and outside of the compressor, improving efficiency of main machine and prolonging the service life.

7. High efficiency, quiet, low vibration, installation without foundation required, convenient for customer maintenance, confirming to ISO9001 standard and CE.II. Technical specification

Model EU7.5A EU11A EU15A EU18.5A EU22A EU30A EU37A/W EU45A/W Free air delivery/Discharge air pressure (M3/min/ Mpa) 1.2/0.7 1.7/0.7 2.4/0.7 3.1/0.7 3.7/0.7 5.2/0.7 6.5/0.7 7.5/0.7 1.1/0.8 1.6/0.8 2.3/0.8 3/0.8 3.5/0.8 5/0.8 6.3/0.8 7.2/0.8 1/1.0 1.4/1.0 2.2/1.0 2.8/1.0 3.0/1.0 4.1/1.0 5.8/1.0 7.0/1.0 0.8/1.3 1.2/1.3 1.7/1.3 2.3/1.3 2.5/1.3 3.7/1.3 25.0/1.3 6.0/1.3 Air supply temperature ≤ambient temperature +8~`15ºC Motor Power (kw/hp) 7.5/10 11/15 15/20 18.5/25 22/30 30/40 37/50 45/60 Start method Y-△Starter Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd can be customized ) Drive method V-belt transmission / Coupling transmission Oil content (PPM) ≤3 Connector inch 3/4″ 3/4″ 1″ 1″ 1″ 1 1/4″ 1 1/4″ 1 1/2″ Noise(Db)±2 56 58 60 60 60 66 66 66 Dimension length mm 900 1060 1060 1080 1080 1300 1300 1300 width mm 700 800 800 880 880 1100 1100 1100 height mm 1040 1230 1230 1420 1420 1650 1650 1650 Weight (kg) 400 500 550 650 680 1000 1050 1100 III. CE & ISO Certificates:

Package photos:

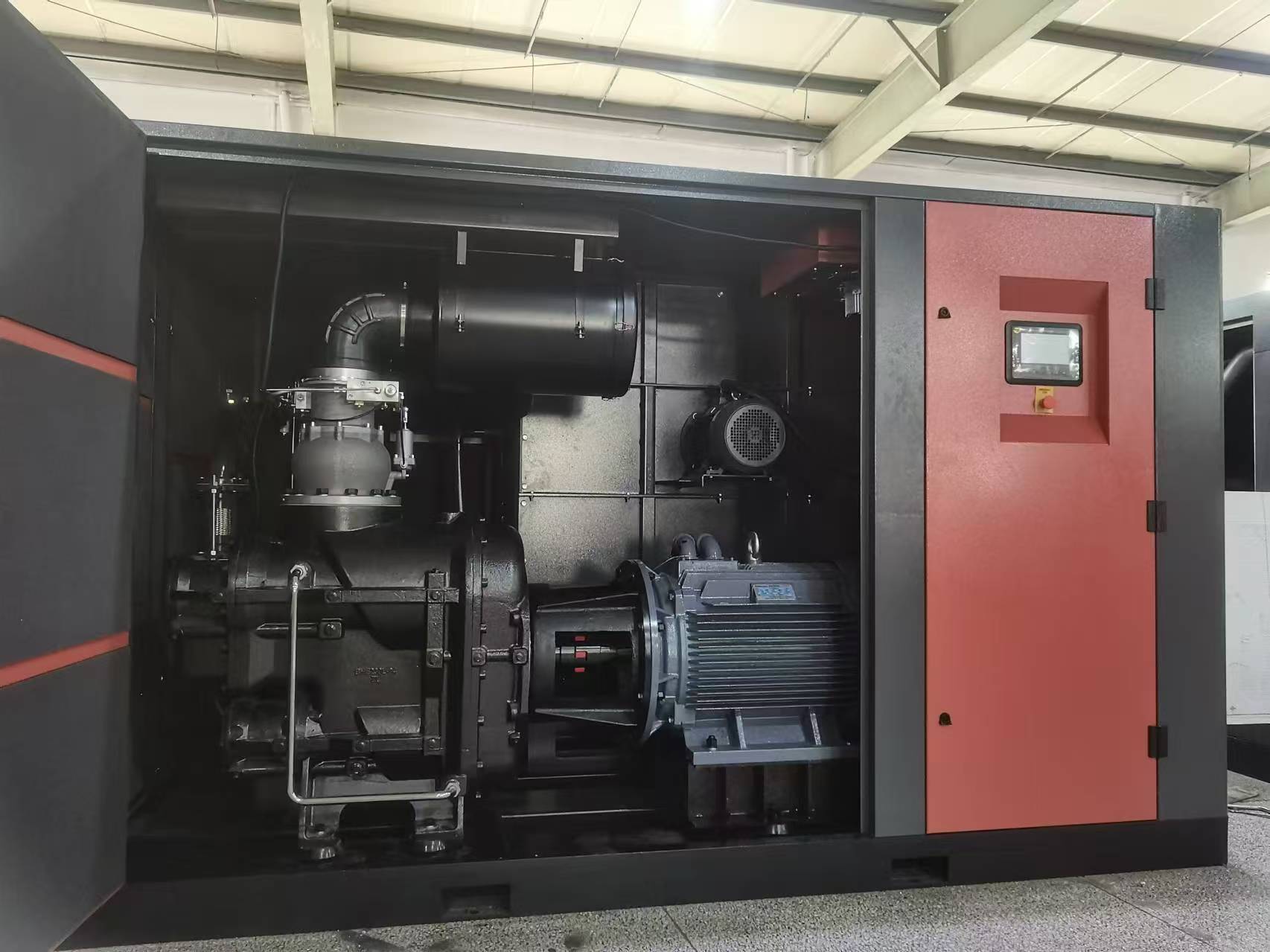

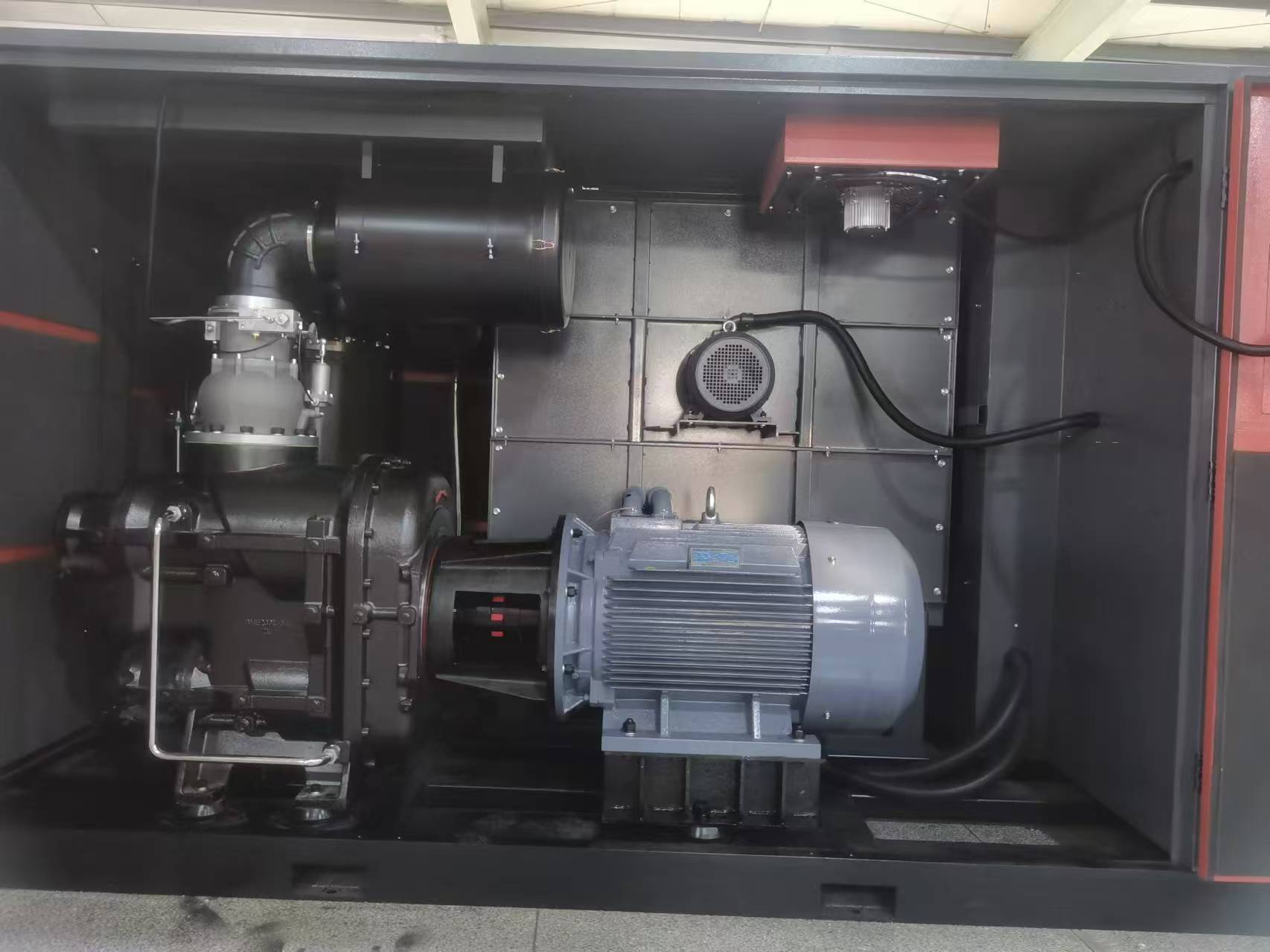

On-site photos:

IV. Company IntroductionSHANGHAI HONEST COMPRESSOR CO., LTD. is one UK wholly-owned compressor company, which was situated in shanghai in 2004, based in technical cooperation with European air end manufacturer and British O.S.G. OSG Shanghai specializes in manufacturing the world-class screw compressors and air purification equipments.

In order to meet customers’ expectations and requirements, OSG shanghai integrates the compressing system to embody the merits of reliability, energy saving, silence, convenience. OSG Shanghai had obtained the compressor production license (certificate No: XK06-010-00597), quality certificate and general machinery certificate, ISO 9001:2008 certificate and CE certificate.

OSG has established a nation-wide service system of 40 offices, and provided comprehensive services, such as consulting, training, repairing, spare parts supplying, etc. OSG shanghai also do OEM for trading companies and agents, according to their requirements.

OSG shanghai welcome customers and engineers all over the world to study, train and cooperate. Welcome to OSG Shanghai.V. Company Advantages

1.Enormous potentiality, long history

Shanghai Honest Compressor Co., Ltd. is one British wholly-owned enterprise. Currently in China, OSG has set up three major manufacturing bases (Shanghai Honest Compressor Co., Ltd, Zhejiang Ulite Tools Co.,Ltd., Guangdong OSG welding), five Manufacturers. Meanwhile we cooperate with the European world-advance air end manufacturer. OSG shanghai possesses a complete production, sales and after-sales service system. OSG has 40 offices and more than 80 after-sales service centers, and products are sold to more than 20 countries.2. Advanced configuration, world-renowned components, abundant production experience.

The control system is the most advanced. The controller is designed and manufactured by Schneider, France. It is equipped with the large Chinese-English liquid crystal display screen. It can monitor more than 20 main operating parameters, and has the functions of fault recording, maintenance and alarm shutdown. It can achieve efficient intelligent control, unattended.

Remote control: the computer processor can directly check the user’s real-time operating system. Combine the reliability, energy saving, practicality in one. remote control can start, stop, load, unload the compressor and also other local control can be carried out. The operation, alarm and fault and relative local information can be monitored. (detailed description followed)

Remote control function:

Multiple compressors remote centralized control: reduce system pressure, reduce energy consumption, real-time monitoring.

Dual pressure setting: Two system pressure bands can be set manually or automatically to optimize energy use and reduce operating costs.

Delayed secondary shutdown: This function controls the motor to run only when needed, allowing the motor to run less and minimize the energy consumption. -

Hot Sale China Factory High Quality Screw Vacuum Pump Permanent Magnet Frequency Conversion Progressive Pump

High-efficiency permanent magnet motor

Insulation grade F, protection grade IP55, soft start operation, stable flow. The constant torque range and weak magnetic range are wider, and the efficiency of permanent magnet motor is 20-30% higher than that of ordinary motor.Integrated frequency converter

Adopts the domestic top frequency conversion system, with a wide speed regulation range and high precision. Stable quality, ensuring pressure transmitter signal transmission.Intelligent touch controller

Superior built-in intelligence, requiring minimal manual operation. High-precision color electronic screen, clear graphic display, and indication of maintenance information, fault alarm, and safe shutdown alarm.Special type intake valve

Automatically controls the opening to ensure engine fuel injection and lubricating oil circulation.

Ultra-low oil circuit loss, improved overall efficiency.

Normal open solenoid valve control, automatic shutdown in emergency shutdown to prevent oil injection.Cooling system

Large heat exchange area design, effectively prevents high temperature of the machine, and reduces oil emulsification and coking caused by high temperature.Excellent air filter

The air filter with excellent air purification ability ensures the cleanliness of the air system, three-stage filtration, maximum air purification, and standard emission. It can remove a large amount of steam and a small amount of dust gas, and the ultimate vacuum can reach 1Pa.Reliable oil and gas separator

Vertical tangential cyclone separation structure, complete separation of oil and gas, easy replacement of filter cartridges, and reduced maintenance costs.High-quality sound insulation cotton

Compact noise reduction housing, no amplitude during operation, combined with high-quality sound insulation cotton, further improves the noise reduction level.Iron oil pipe and air pipe system

Iron is resistant to high temperature, low temperature, and high pressure, suitable for harsh working conditions, completely leak-free and maintenance-free.Advantages:

Multiple filtration

Three-stage filtration minimizes air impurities.Energy saving

Saves 50-60% of electricity compared to traditional vacuum pumps.Constant pressure

Constant speed pumping, solving the problem of unstable vacuum pumping.Higher vacuum degree

The vacuum degree of the vacuum pump on the market is -0.07Mpa, our vacuum degree is -0.098Mpa.Easy use

Simple structure, easy to install, operate, and maintain. -

37kw 50HP Two Stage VFD PM series Two-stage Compression Screw Air Compressor

37kw 50HP Two Stage VFD PM series Two-stage Compression Screw Air Compressor

Technical advantages of single motor two-stage compression screw air compressor:

1. Low noise Unique rotor profile allows the main engine to run at low speed and low vibration Graded compression effectively reduces pipeline pulses, vibrations, and noise

2. High reliability Unique rotor profile allows the yin and yang rotors to be highly meshed and have a long service life Graded compression effectively reduces gas leakage and is conducive to the formation of an oil film to protect the rotor Excellent pressure ratio distribution reduces bearing load, allowing the bearing life to reach 25,000 hours

3. Super energy saving Adopting superior pressure ratio distribution greatly improves compression efficiency Adopting interstage cooling, close to isothermal compression Two-stage compression, the pressure ratio of each stage decreases, which can effectively reduce power The entire series meets the national first-level energy efficiency standards and saves energy consumption. Won the national 2023 enterprise standard “leader”

ETS- series technical parameters: Model ETS-18A ETS-22A ETS-30A ETS-37A/W ETS-45A/W ETS-55A/W ETS-75A/W ETS-90A/W ETS-110A/W ETS-132A/W ETS-160A/W ETS-185A/W ETS-200A/W ETS-220A/W ETS-250W ETS-280A/W ETS-315A/W ETS-355W Model ETSV-18A ETSV-22A ETSV-30A ETSV-37A/W ETSV-45A/W ETSV-55A/W ETSV-75A/W ETSV-90A/W ETSV-110A/W ETSV-132A/W ETSV-160A/W ETSV-185A/W ETSV-200A/W ETSV-220A/W ETSV-250W ETSV-280A/W ETSV-315A/W ETSV-355W Free air delivery/Discharge air pressure (M3/min/ Mpa) 3.5/0.7 4.1/0.7 6.5/0.7 7.1/0.7 9.8/0.7 12.8/0.7 17.6/0.7 21.0/0.7 24.5/0.7 29.9/0.7 34.5/0.7 41.0/0.7 44.7/0.7 48.6/0.7 55.0/0.7 61.0/0.7 69.0/0.7 78.0/0.7 3.4/0.8 4.0/0.8 6.4/0.8 7.0/0.8 9.7/0.8 12.4/0.8 16.6/0.8 19.8/0.8 23.6/0.8 28.0/0.8 15.8/0.8 20.0/0.8 43.0/0.8 46.9/0.8 54.0/0.8 59.9/0.8 67.6/0.8 76.0/0.8 3.0/1.0 3.4/1.0 4.8/1.0 6.2/1.0 7.8/1.0 9.7/1.0 12.4/1.0 17.9/1.0 19.8/1.0 23.5/1.0 14.2/1.0 17.5/1.0 38.5/1.0 41.0/1.0 45.9/1.0 51.0/1.0 61.0/1.0 69.0/1.0 2.4/1.3 3.2/1.3 4.1/1.3 5.5/1.3 6.6/1.3 8.7/1.3 11.1/1.3 14.2/1.3 17.5/1.3 19.8/1.3 11.6/1.3 14.3/1.3 32.9/1.3 38.0/1.3 40.0/1.3 44.9/1.3 51.0/1.3 58.0/1.3 Air supply temperature ≤ambient temperature +8~15ºC Motor Power (kw/hp) 18.5/25 22/30 30/40 37/50 45/60 55/75 75/100 90/120 110/150 132/175 160/215 185/250 200/270 220/294 250/355 280/375 315/420 355/475 Start method Y-△Starter/VSD start Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd can be customized ) Drive method Coupling transmission Oil content (PPM) ≤3 Connector inch 1″ 1″ 1″ 1 1/4″ 2″ 2″ 2″ DN65 DN65 DN65 DN80 DN100 DN100 DN100 DN100 DN100 DN125 DN125 Dimension length mm 1500 1500 1800 1800 2100 2100 2200 2700 2700 2800 2800 3200 3200 3200 3550 3550 3750 3750 width mm 900 900 1100 1100 1260 1260 1260 1600 1600 1700 1800 2200 2200 2200 2300 2300 2400 2400 height mm 1150 1150 1350 1350 1600 1600 1600 1950 1950 1900 1900 2300 2300 2300 2350 2350 2350 2350 Weight (kg) 680 730 980 1080 1628 1700 2256 2280 3300 3750 3770 3990 4890 5500 6000 6500 7000 7500 Weight (kg) 665 700 950 1000 1590 1650 2200 2230 3200 3300 3600 3800 4700 5300 5850 6340 6850 6300 -

VFD PM Two Stage Screw Air Compressor 315kw 1.3Mpa Variable Frequency Permanent Magnet Screw Air Compressor with Level 1 energy consumption

VFD PM Two Stage Screw Air Compressor 315kw 1.3Mpa Variable Frequency Permanent Magnet Screw Air Compressor with Level 1 energy consumption

1.Displacement 10%-15% higher than ordinary piston compressor. 2. Compared with single stage air compressor, two stage series with excellent energy saving. 3. 24 hours unattended all day work, free load automatically start, full load automatically shut down. 4. Displacement and pressure stable Under long time working, , no crash phenomenon, low failure rate. 5.Intelligent microcomputer-based control technology can monitor and control Remote control realizes unattended operation, and the user-friendly human-machine interface displays instructions and parameters in written form. Also, it can function to self diagnose faults, give warning and automatically regulate the capacity. Advantage:

Sufficient exhaust volume

Constant air pressure

Energy Saving

Environment Protection

Sturdy body

Low gas leakage

More energy saving with Level 1 energy consumption

Testing:

All of our compressor should be tested at least 2-3 hours before delivery to ensure the quality .for some customized model ,the testing should be 8-10 hours.

Packing:

Except the big size compressor ,others are all with standard wooden packing.

-

Oil Cooled Screw Air Compressor 55kw 75hp Industrial Air Compressor Rotary Air Compressor

Oil Cooled Screw Air Compressor 55kw 75hp Industrial Air Compressor Rotary Air Compressor Advantages and features New generation appearance design, new structure, stable quality. Coaxial transmission mode is adopted, with higher transmission efficiency and zero transmission efficiency loss. IE5 permanent magnet variable frequency motor is adopted, and the speed can be freely changed according to customer needs. Fully sealed liquid-cooled motor housing, IP65 protection factor. The suspended coaxial direct-connected integrated structure can minimize mechanical loss, ensure the life of the motor, improve transmission efficiency, and reduce floor space with a compact design. Frequency conversion controller: It uses frequency conversion to provide stable pressure and gas conditions suitable for customers. Professional heat dissipation design can operate at an ambient temperature of 50°C, automatically adjust the output rating according to the temperature rise condition, and maintain the inverter to work continuously and efficiently. IP65 liquid-cooled permanent magnet motor The IE5 liquid-cooled permanent magnet motor and IP65 fully sealed protection fully protect the safety of the permanent magnet motor, so you don’t have to worry about the reliability of the motor. Jaguar aftercooler: The high-efficiency cooler has a significant cooling effect; even in harsh operating environments such as high temperature and high humidity, it can ensure the normal operation of the air compressor. Heavy-duty air filter: The unique air intake box system prevents dust from entering the system; it filters fine particles in the air to ensure the quality of the air entering the head and extend the life of the main engine. Application scope: Widely used in energy industry, textile manufacturing industry, machinery manufacturing industry, chemical manufacturing industry and other industries. Ensure reliable production and manufacturing operations and achieve safe, reliable and stable industrial production.

-

11kw 15Hp Low Noise Water Lubricating Oil Free Screw Air Compressor oilless industrial air compressor rotary air compressor

Advantage for fixed speed type:

Self-learning function,intelligent start/stop

Detect the ambient temperature to prevent the ambient temperature from being too high temperature to cause high temperature failure.

Detect tge terminal pressure of the post-treatment equipment to effectively prevent the compressed air pressure different from being too high to waste electric energy

Detect the motor’s temperature to protect it.

Constant pressure control:high precision constant pressure control with a pressure fluctuation range within 0.01mpa.

Variable frequency soft start: remove peak current during starting,avoid the power grid impact,prevent the current impact through gradual speed regulation and improve flexibility.

No idling:prevent idling of the compressor during running and reduce invalid energy consumption.the permanent magnet motor adopts a high efficiency rare earth magnet,without loss of excitation at 180,providing a long service life and saving about 6%-7% .more energy than an ordinary variable frequency motor,obtain the maximum efficiency within a wider range to make the air compressor more energy efficient

High performance vector control:low-frequency starting provides a large torque and a low running current,ensuring to get a reasonable torque to drive the air compressor to run stably with the minimum temperature rise of the motor with a wide speed range.

Q1: Are you a factory or trade company?

A1: We have two factories which locates in Shanghai and Jiangxi.Q2: What the exact address of your company?

A2: No.1071,Yongxin Road,Xuhang Town, Jiading District, Shanghai, ChinaQ3: Warranty terms of your machine?

A3:13 months for the delivery date..Q4: How long is your delivery?

A4: 7-30 days after receiving your 30% down payment.Q5: Terms of payment?

A5: T/T and L/C at sight.Q6: What is the MOQ?

A6: 1 unit.Q7: Can you accept OEM orders?

A7: Yes, with a professional design team, OEM or ODM orders are highly welcome.Q8: Can you accept color customization?

A8: Yes we can,such as color.Q9: Will you provide some spare parts for the air compressor?

A9: Yes, of course.Q10: What’s your factory’s production capacity for this series?

A10: About 1000 units per year -

Two-stage Compression power frequency 132kw high power Energy-Saving Screw Air Compressor for industrial and mining

Two-stage Compression power frequency 132kw high power Energy-Saving Screw Air Compressor for industrial and mining

Place of Origin shanghai, China Warranty 1 Year Working Pressure 8bar/10bar Machinery Test Report Provided Video outgoing-inspection Provided Warranty of core components 1 years Core Components PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox Gas Type Air Type Screw Configuration Stationary Power Source AC POWER Lubrication Style Lubricated Brand Name OSG Model Number ETSVII-132A Voltage 380v/3hp/50hz, 240v/3ph/60hz(or Customized) Cooling air cooling Application General Industry Cooling System Ar Cooling Compression Stage 1 Stage Certification CE/ISO Service

1.24/7 air compressor service support

2.Factory-trained and experienced air compressor service technicians

3.All kinds of technical documents in different languages

4.Technical training for customers in OSG air compressor factory or working site

5.Plenty of original spare parts with proven quality in stock

6.Guidance of installation is available by engineers of OSG air compressor factory or local distributors

7.Air compressor maintenance and troubleshooting solution provided in 24 hours

8.Follow up the feedback of air compressors in 2months interval by e-mail or call

9.OSG service ensures continuous end-to-end care of all compressed air systems including Non-OSG

FAQ:

Q1: Are you factory or trade company?

A1: We are factory.Q2: Warranty terms of your machine?

A2: Two years warranty for the machine and technical support according to your needs.Q3: Will you provide some spare parts of the machines?

A3: Yes, of course.Q4: How long will you take to arrange production?

A4: 380V 50HZ we can delivery the goods within 10 days. Other electricity or other color we will delivery within 30 daysQ5: Can you accept OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome. -

Two-stage 132kw high power Energy-Saving Screw Air Compressor with Variable Frequency Permanent Magnet

Two-stage 132kw high power Energy-Saving Screw Air Compressor with Variable Frequency Permanent Magnet

Place of Origin shanghai, China Warranty 1 Year Working Pressure 8bar/10bar Machinery Test Report Provided Video outgoing-inspection Provided Warranty of core components 1 years Core Components PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox Gas Type Air Type Screw Configuration Stationary Power Source AC POWER Lubrication Style Lubricated Brand Name OSG Model Number ETSV-132A Voltage 380v/3hp/50hz, 240v/3ph/60hz(or Customized) Cooling air cooling Application General Industry Cooling System Ar Cooling Compression Stage 1 Stage Certification CE/ISO Service

1.24/7 air compressor service support

2.Factory-trained and experienced air compressor service technicians

3.All kinds of technical documents in different languages

4.Technical training for customers in OSG air compressor factory or working site

5.Plenty of original spare parts with proven quality in stock

6.Guidance of installation is available by engineers of OSG air compressor factory or local distributors

7.Air compressor maintenance and troubleshooting solution provided in 24 hours

8.Follow up the feedback of air compressors in 2months interval by e-mail or call

9.OSG service ensures continuous end-to-end care of all compressed air systems including Non-OSG

FAQ:

Q1: Are you factory or trade company?

A1: We are factory.Q2: Warranty terms of your machine?

A2: Two years warranty for the machine and technical support according to your needs.Q3: Will you provide some spare parts of the machines?

A3: Yes, of course.Q4: How long will you take to arrange production?

A4: 380V 50HZ we can delivery the goods within 10 days. Other electricity or other color we will delivery within 30 daysQ5: Can you accept OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome. -

Energy saving permanent Magnet Motor VSD screw air compressor 11Kw 15HP with Dryers built in

Energy saving permanent Magnet Motor VSD screw air compressor 11Kw 15HP with Dryers built in

1. Energy saving 30-50% on average by permanent Magnet Motor VSD screw air compressor .

2.high volume,high efficiency.

3.Permanent magnetic electric motor 100% transmission

4.Intelligent touch screen control panel

5.Unique design with inverter to protect from short phase, phase short circuit, ground short circuit, over current, over voltage, under voltage, overload, overheating, motor thermal protections etc.

6.Air dryer and adsorption dryer built in to save space and installation cost.

-

7.5kw 10HP AC Power Screw Compressor Fixed Speed Screw Air Compressor Industrial Air Compressor

DIRECT DRIVEN SCREW AIR COMPRESSOR7.5kw 10HP AC Power Screw Compressor Fixed Speed Screw Air Compressor Industrial Air CompressorSHORT DESCRIPTION:

Double Screw with low noise, Super Silenced Enclosure

Elegant compact design. Fully open access door to inner parts for easy service.100% Continuous duty operation. Load/No Load operationHigh quality CE Certificate industrial electric motors.Easy to use and read LCD control panelHigh temperature, high pressure and anti-rotation shutdownSupply the machine with different working voltage according to customer’s request, such as:380Volt, 3Phase, 50Hz / 410Volt, 3Phase, 50Hz/415Volt, 3Phase, 60Hz / 220Volt, 3Phase, 60Hz etcWhat we can supply:* Oil-injected Screw Air Compressor /oil free screw air compressor and blower

* All-in-one Screw Air Compressor with Tank, Dryer, and Filters

* Single-phase Small Screw Air Compressor

* Water-injected Oil-free Screw Air Compressor

* Oil-free Scroll Air Compressor

* Diesel&Electric Engine Portable Screw Air Compressor

* Air Dryer, Air tank, Filters, and other Spare parts for our compressor,more details please check our website.

Type:fixed speed ,VFD pm

Cooling ways:air cooling and water cooling and oil cooling

-

Four In One 7.5kw 10HP AC Power Screw Compressor Fixed Speed Screw Air Compressor Industrial Air Compressor

DIRECT DRIVEN SCREW AIR COMPRESSOR7.5kw 10HP AC Power Screw Compressor Fixed Speed Screw Air Compressor Industrial Air CompressorSHORT DESCRIPTION:

Double Screw with low noise, Super Silenced Enclosure

Elegant compact design. Fully open access door to inner parts for easy service.100% Continuous duty operation. Load/No Load operationHigh quality CE Certificate industrial electric motors.Easy to use and read LCD control panelHigh temperature, high pressure and anti-rotation shutdownSupply the machine with different working voltage according to customer’s request, such as:380Volt, 3Phase, 50Hz / 410Volt, 3Phase, 50Hz/415Volt, 3Phase, 60Hz / 220Volt, 3Phase, 60Hz etcWhat we can supply:

* Oil-injected Screw Air Compressor /oil free screw air compressor and blower

* All-in-one Screw Air Compressor with Tank, Dryer, and Filters

* Single-phase Small Screw Air Compressor

* Water-injected Oil-free Screw Air Compressor

* Oil-free Scroll Air Compressor

* Diesel&Electric Engine Portable Screw Air Compressor

* Air Dryer, Air tank, Filters, and other Spare parts for our compressor,more details please check our website.

Type:fixed speed ,VFD pm

Cooling ways:air cooling and water cooling and oil cooling

-

55KW 75HP 7-13bar air compressor two stage screw air compressor Direct Drive Screw Type Compressors with VSD PM motor and Inverter

1. No gears to ensure more stable operation and lower noise;

2. Unique design,up and down structure to ensure less vibration, more stable and easy to operation;

3. Dual air ends, double frequency conversion, step-less speed change,to make the air end always running at an energy-saving speed to saving more energy;

4 IP55 or IP54 for optional ,fully enclosed motor controlled in a good state, with higher efficiency and safety.