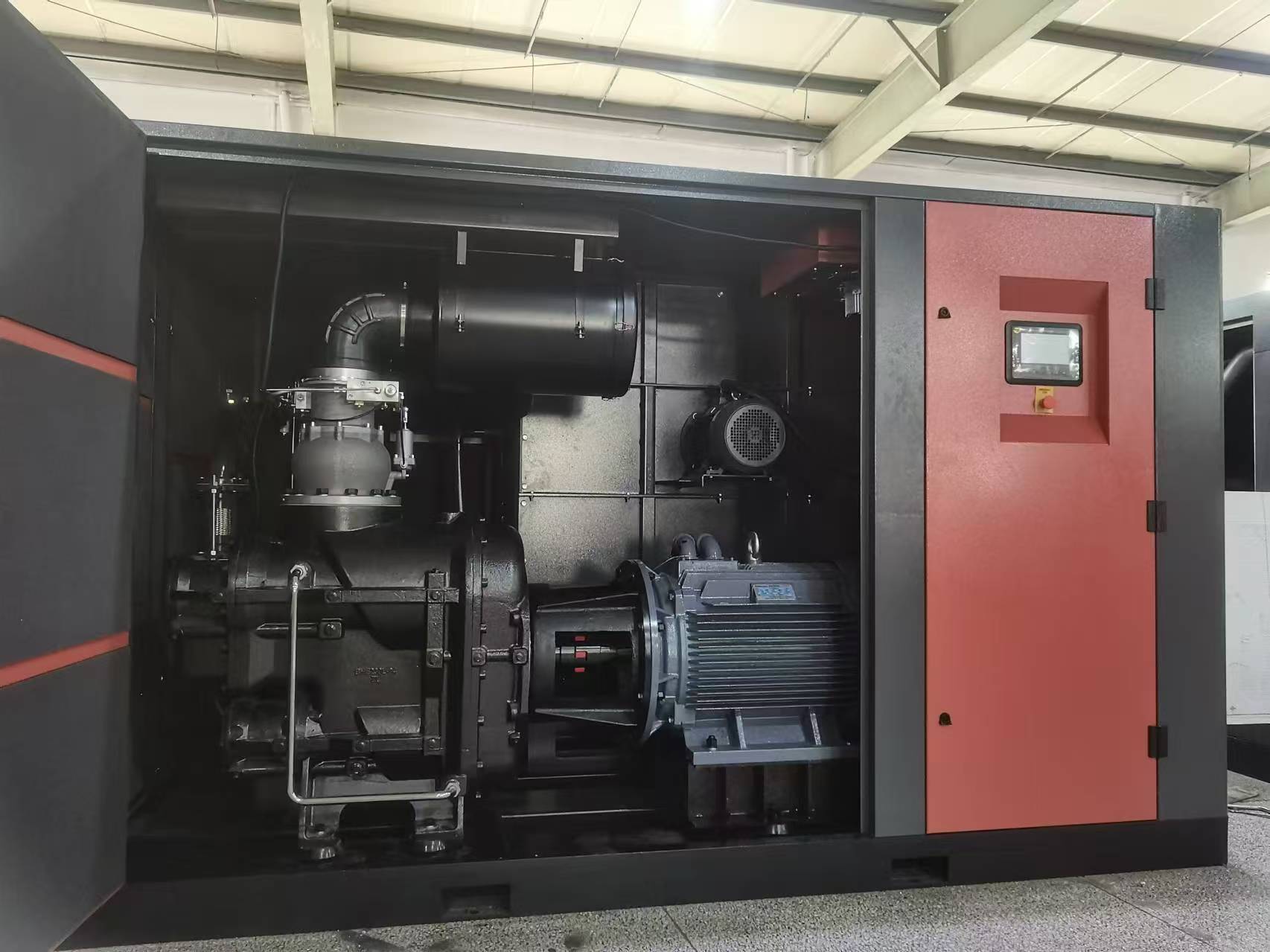

Up and down structure Two-Stage Screw Air Compressor

-

37kw 50HP Two Stage VFD PM series Two-stage Compression Screw Air Compressor

37kw 50HP Two Stage VFD PM series Two-stage Compression Screw Air Compressor

Technical advantages of single motor two-stage compression screw air compressor:

1. Low noise Unique rotor profile allows the main engine to run at low speed and low vibration Graded compression effectively reduces pipeline pulses, vibrations, and noise

2. High reliability Unique rotor profile allows the yin and yang rotors to be highly meshed and have a long service life Graded compression effectively reduces gas leakage and is conducive to the formation of an oil film to protect the rotor Excellent pressure ratio distribution reduces bearing load, allowing the bearing life to reach 25,000 hours

3. Super energy saving Adopting superior pressure ratio distribution greatly improves compression efficiency Adopting interstage cooling, close to isothermal compression Two-stage compression, the pressure ratio of each stage decreases, which can effectively reduce power The entire series meets the national first-level energy efficiency standards and saves energy consumption. Won the national 2023 enterprise standard “leader”

ETS- series technical parameters: Model ETS-18A ETS-22A ETS-30A ETS-37A/W ETS-45A/W ETS-55A/W ETS-75A/W ETS-90A/W ETS-110A/W ETS-132A/W ETS-160A/W ETS-185A/W ETS-200A/W ETS-220A/W ETS-250W ETS-280A/W ETS-315A/W ETS-355W Model ETSV-18A ETSV-22A ETSV-30A ETSV-37A/W ETSV-45A/W ETSV-55A/W ETSV-75A/W ETSV-90A/W ETSV-110A/W ETSV-132A/W ETSV-160A/W ETSV-185A/W ETSV-200A/W ETSV-220A/W ETSV-250W ETSV-280A/W ETSV-315A/W ETSV-355W Free air delivery/Discharge air pressure (M3/min/ Mpa) 3.5/0.7 4.1/0.7 6.5/0.7 7.1/0.7 9.8/0.7 12.8/0.7 17.6/0.7 21.0/0.7 24.5/0.7 29.9/0.7 34.5/0.7 41.0/0.7 44.7/0.7 48.6/0.7 55.0/0.7 61.0/0.7 69.0/0.7 78.0/0.7 3.4/0.8 4.0/0.8 6.4/0.8 7.0/0.8 9.7/0.8 12.4/0.8 16.6/0.8 19.8/0.8 23.6/0.8 28.0/0.8 15.8/0.8 20.0/0.8 43.0/0.8 46.9/0.8 54.0/0.8 59.9/0.8 67.6/0.8 76.0/0.8 3.0/1.0 3.4/1.0 4.8/1.0 6.2/1.0 7.8/1.0 9.7/1.0 12.4/1.0 17.9/1.0 19.8/1.0 23.5/1.0 14.2/1.0 17.5/1.0 38.5/1.0 41.0/1.0 45.9/1.0 51.0/1.0 61.0/1.0 69.0/1.0 2.4/1.3 3.2/1.3 4.1/1.3 5.5/1.3 6.6/1.3 8.7/1.3 11.1/1.3 14.2/1.3 17.5/1.3 19.8/1.3 11.6/1.3 14.3/1.3 32.9/1.3 38.0/1.3 40.0/1.3 44.9/1.3 51.0/1.3 58.0/1.3 Air supply temperature ≤ambient temperature +8~15ºC Motor Power (kw/hp) 18.5/25 22/30 30/40 37/50 45/60 55/75 75/100 90/120 110/150 132/175 160/215 185/250 200/270 220/294 250/355 280/375 315/420 355/475 Start method Y-△Starter/VSD start Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd can be customized ) Drive method Coupling transmission Oil content (PPM) ≤3 Connector inch 1″ 1″ 1″ 1 1/4″ 2″ 2″ 2″ DN65 DN65 DN65 DN80 DN100 DN100 DN100 DN100 DN100 DN125 DN125 Dimension length mm 1500 1500 1800 1800 2100 2100 2200 2700 2700 2800 2800 3200 3200 3200 3550 3550 3750 3750 width mm 900 900 1100 1100 1260 1260 1260 1600 1600 1700 1800 2200 2200 2200 2300 2300 2400 2400 height mm 1150 1150 1350 1350 1600 1600 1600 1950 1950 1900 1900 2300 2300 2300 2350 2350 2350 2350 Weight (kg) 680 730 980 1080 1628 1700 2256 2280 3300 3750 3770 3990 4890 5500 6000 6500 7000 7500 Weight (kg) 665 700 950 1000 1590 1650 2200 2230 3200 3300 3600 3800 4700 5300 5850 6340 6850 6300 -

VFD PM Two Stage Screw Air Compressor 315kw 1.3Mpa Variable Frequency Permanent Magnet Screw Air Compressor with Level 1 energy consumption

VFD PM Two Stage Screw Air Compressor 315kw 1.3Mpa Variable Frequency Permanent Magnet Screw Air Compressor with Level 1 energy consumption

1.Displacement 10%-15% higher than ordinary piston compressor. 2. Compared with single stage air compressor, two stage series with excellent energy saving. 3. 24 hours unattended all day work, free load automatically start, full load automatically shut down. 4. Displacement and pressure stable Under long time working, , no crash phenomenon, low failure rate. 5.Intelligent microcomputer-based control technology can monitor and control Remote control realizes unattended operation, and the user-friendly human-machine interface displays instructions and parameters in written form. Also, it can function to self diagnose faults, give warning and automatically regulate the capacity. Advantage:

Sufficient exhaust volume

Constant air pressure

Energy Saving

Environment Protection

Sturdy body

Low gas leakage

More energy saving with Level 1 energy consumption

Testing:

All of our compressor should be tested at least 2-3 hours before delivery to ensure the quality .for some customized model ,the testing should be 8-10 hours.

Packing:

Except the big size compressor ,others are all with standard wooden packing.

-

Two-stage Compression power frequency 132kw high power Energy-Saving Screw Air Compressor for industrial and mining

Two-stage Compression power frequency 132kw high power Energy-Saving Screw Air Compressor for industrial and mining

Place of Origin shanghai, China Warranty 1 Year Working Pressure 8bar/10bar Machinery Test Report Provided Video outgoing-inspection Provided Warranty of core components 1 years Core Components PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox Gas Type Air Type Screw Configuration Stationary Power Source AC POWER Lubrication Style Lubricated Brand Name OSG Model Number ETSVII-132A Voltage 380v/3hp/50hz, 240v/3ph/60hz(or Customized) Cooling air cooling Application General Industry Cooling System Ar Cooling Compression Stage 1 Stage Certification CE/ISO Service

1.24/7 air compressor service support

2.Factory-trained and experienced air compressor service technicians

3.All kinds of technical documents in different languages

4.Technical training for customers in OSG air compressor factory or working site

5.Plenty of original spare parts with proven quality in stock

6.Guidance of installation is available by engineers of OSG air compressor factory or local distributors

7.Air compressor maintenance and troubleshooting solution provided in 24 hours

8.Follow up the feedback of air compressors in 2months interval by e-mail or call

9.OSG service ensures continuous end-to-end care of all compressed air systems including Non-OSG

FAQ:

Q1: Are you factory or trade company?

A1: We are factory.Q2: Warranty terms of your machine?

A2: Two years warranty for the machine and technical support according to your needs.Q3: Will you provide some spare parts of the machines?

A3: Yes, of course.Q4: How long will you take to arrange production?

A4: 380V 50HZ we can delivery the goods within 10 days. Other electricity or other color we will delivery within 30 daysQ5: Can you accept OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome. -

Two-stage 132kw high power Energy-Saving Screw Air Compressor with Variable Frequency Permanent Magnet

Two-stage 132kw high power Energy-Saving Screw Air Compressor with Variable Frequency Permanent Magnet

Place of Origin shanghai, China Warranty 1 Year Working Pressure 8bar/10bar Machinery Test Report Provided Video outgoing-inspection Provided Warranty of core components 1 years Core Components PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox Gas Type Air Type Screw Configuration Stationary Power Source AC POWER Lubrication Style Lubricated Brand Name OSG Model Number ETSV-132A Voltage 380v/3hp/50hz, 240v/3ph/60hz(or Customized) Cooling air cooling Application General Industry Cooling System Ar Cooling Compression Stage 1 Stage Certification CE/ISO Service

1.24/7 air compressor service support

2.Factory-trained and experienced air compressor service technicians

3.All kinds of technical documents in different languages

4.Technical training for customers in OSG air compressor factory or working site

5.Plenty of original spare parts with proven quality in stock

6.Guidance of installation is available by engineers of OSG air compressor factory or local distributors

7.Air compressor maintenance and troubleshooting solution provided in 24 hours

8.Follow up the feedback of air compressors in 2months interval by e-mail or call

9.OSG service ensures continuous end-to-end care of all compressed air systems including Non-OSG

FAQ:

Q1: Are you factory or trade company?

A1: We are factory.Q2: Warranty terms of your machine?

A2: Two years warranty for the machine and technical support according to your needs.Q3: Will you provide some spare parts of the machines?

A3: Yes, of course.Q4: How long will you take to arrange production?

A4: 380V 50HZ we can delivery the goods within 10 days. Other electricity or other color we will delivery within 30 daysQ5: Can you accept OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome. -

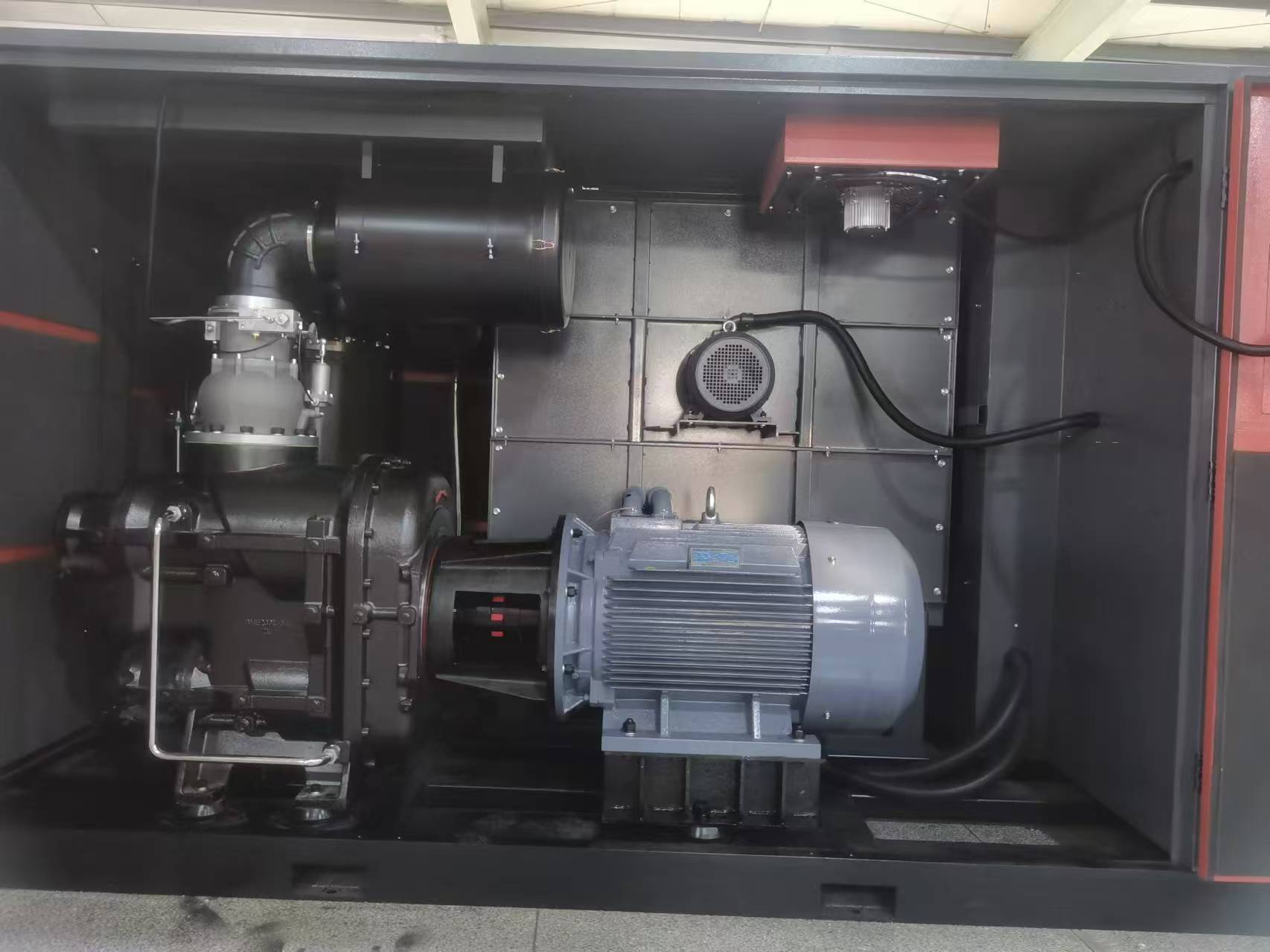

55KW 75HP 7-13bar air compressor two stage screw air compressor Direct Drive Screw Type Compressors with VSD PM motor and Inverter

1. No gears to ensure more stable operation and lower noise;

2. Unique design,up and down structure to ensure less vibration, more stable and easy to operation;

3. Dual air ends, double frequency conversion, step-less speed change,to make the air end always running at an energy-saving speed to saving more energy;

4 IP55 or IP54 for optional ,fully enclosed motor controlled in a good state, with higher efficiency and safety.

-

IP55/54 55KW 75HP Factory Price Two Stage Industrial Screw Type Air Compressor Machine

IP55/54 55KW 75HP Factory Price Two Stage Industrial Screw Type Air Compressor Machine

SHORT DESCRIPTION:

1. No gears, no traditional faults such as couplings, no bearings for the motor, more stable operation and less noise;

2. Unique design, dual hosts, dual motors, horizontal placement, less vibration, more stable and comfortable operation;

3. Dual air ends, double frequency conversion, stepless speed change, so that the host is always running at an energy-saving speed, more energy-saving;

Oil-cooled IP55 fully enclosed motor, the motor is controlled in a good state, with higher efficiency and safety.

Technical information

Model:ETSV-55A Power(KW) 55KW Horse(HP) 75 HP Pressure Bar M³/min 7/8/10/13 12.8/12.4/9.7/8.76.2 Exhaust temperature ≤ +8ºC Intake air temperature No more than 45 degree centigrade Noise dB(A) ≤68±2 Oil content (ppm) ≈3 Power V/pb/Hz 380/3/50 or as your request L×W×H mm 2100*1260*1600 Weight (kg) 1700KGS Diameter of outlet 2” Applicable Industries General Industry Place of Origin Shanghai, China Warranty 13 months from the delivery date Working Pressure 7 bar, 8 bar, 10 bar,13 bar Machinery Test Report Video outgoing-inspection Gas Type Air Condition New Type Screw Power Source AC POWER Lubrication Style Lubricated Brand Name OSG Voltage 220V / 230V / 380V / 400V / 440V / 460V / 600V or others After-sales Service Provided Engineers available to service machinery overseas Cooling Method Air Cooling / Water Cooling Drive Method Direct Driven / Coupling Color Red and grey / Customize OEM / ODM Offered / Suppied Insulation Grade F Protection Grade IP54 /IP55 Exhaust Oil Content < 3ppm -

Oil-cooled two-stage permanent magnet variable frequency screw air compressor

1. No gears, no traditional faults such as couplings, no bearings for the motor, more stable operation and less noise;

2. Unique design, dual hosts, dual motors, horizontal placement, less vibration, more stable and comfortable operation;

3. Dual air ends, double frequency conversion, stepless speed change, so that the host is always running at an energy-saving speed, more energy-saving;

Oil-cooled IP55 fully enclosed motor, the motor is controlled in a good state, with higher efficiency and safety.

-

Energy Saving Air Cooling Screw Compressor Two Stage Direct Driven Screw Air Compressor

The two-stage compression oil injection screw air compressor has a reasonable equal pressure ratio, ultra-small leakage, and ultra-low noise host design. It combines the first-stage compression rotor and the second-stage compression rotor in one casing, and directly drives them respectively through the front gear, so that each stage of the rotor can obtain the best line speed matching the gas production during operation, and at the same time, the reasonable compression The ratio can effectively reduce the compression leakage. Therefore, the compression efficiency is much higher than that of single-stage compression. Therefore, compared with single-stage compression, two-stage compression is more energy-efficient.